sierra wrote:coxy47 wrote:

The way to do it is to use the arduino to read the signal to the servo and use this to output the signal of the correct throttle position sensor to the ecu and output a separate signal to the throttle body servo to do what we want. The only difficult part is logging the signal that is applied to the servo and the corresponding signals of the TPS when the system is behaving as it should.

I was assuming that the temp or accelerator pedal reading would be 'changed' or frozen when it arrived at the throttle body, not before that.

Couldn't the arduino receive, say the temp signal and then pass on to the throttle body that the coolant is always 50c?

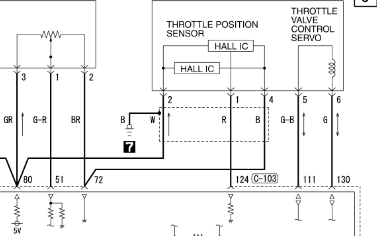

Unfortunately not. There are only 5 wires going to the throttle body. 2 to the servo and 3 for the TPS. This means there is no direct connection from the temp sensor or the acclerator pedal the the throttle body. The throttle body is controlled directly from the ecu and nothing else. So to control what the throttle body does you either have to control the servo directly through something like an arduino processor or reprogram the ecu to send a different signal under separate conditions.

Something like an MRT tune should be able to achieve this.